- ISO 9001: 2015 Certified

- seagullclock@outlook.com

- 01

-

品質管理工程

Product quality is crucial to the business of a company! As an expert company to provide CNC machining service, SEAGULL has a complete quality management system including procedures of quality operation, quality and reliability engineering, and essential quality control. Our product quality inspection can be segmented into four key steps, i.e. incoming quality control, in-process quality control, final quality control and outgoing quality control.

- 02

-

Quality Operation

Responsibilities: development of innovative quality improvement program, operation of quality assurance meetings To maintain customer satisfaction of highest quality products, we implement quality improvement and quality assurance programs through product development, production, supplying and delivery.

- 03

-

Quality and Reliability Engineering

Responsibilities: product planning, design-basis document, quality function deployment (QFD), failure modes and effects analysis (FMEA), critical to quality (CTQ), certification examination, event management, DR and quality assessment meeting, initial product approval, drawings and design changing, finished product approval, environmental and PL events, reliability assurance event.

- 04

-

IQC (Incoming 品質管理)

Responsibilities: designated inspectors strictly execute inspection of raw materials and parts provided by suppliers according to the inspection standards. The inspection results will be recorded and fed back to the relevant departments.

- 05

-

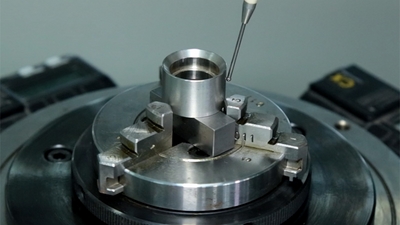

IPQC (In Process 品質管理)

Responsibilities: during the manufacturing process, inspections will be carried out frequently in accordance with the required quality standards. All data will be logged and analyzed for tracking and improvement of unstable products or projects.

- 06

-

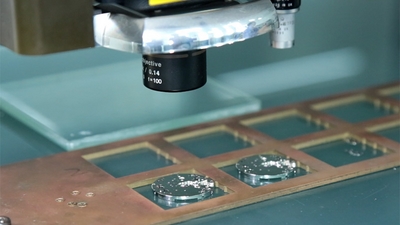

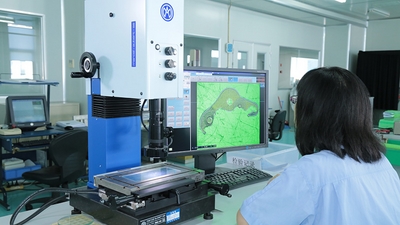

FQC (Final 品質管理)

Responsibilities: every finished part will be completely tested for its appearance, size and performance according to our rigid quality standards. Before entering the storage area, AQL sampling method is used to test samples of finished products, ensuring that the products are compliant with required specification and solve the application needs of customers.

- 07

-

OQC (Outgoing 品質管理)

Our quality inspection staff will randomly inspect the finished products before shipping. This final inspection step is essential to further guarantee defect-free products supplying.

| QUALITY AND INSPECTION EQUIPMENT | ||||

| Equipment | Application | Brand | Accuracy | Quantity |

| Height master | Measure the size and shape of parts | Mitutoyo(JAPAN) | ±0.001mm | 220 |

| Micrometers | Mitutoyo(JAPAN) | ±0.001mm | 200 | |

| Micrometer for measuring root tangent lengths of gear teeth | TESA(SWISS) | ±0.001mm | 20 | |

| Calipers | Mitutoyo(JAPAN) | ±0.01mm | 150 | |

| 3D coordinate measuring machine | Measure the tolerance of form and position | Mitutoyo(JAPAN) | ±0.001mm | 1 |

| 2D measuring instrument | Measure the contour of parts | Marcel Aubert SA(Swiss) | ±0.001mm | 3 |

| Profilometer | Measure the contour & surface roughness of parts | Mitutoyo(JAPAN) | ±0.001mm | 1 |

| Roundness tester | Measure the cylindricity of parts | Mitutoyo(JAPAN) | ±0.001mm | 1 |

| GSM700 Microscopes | ZEISS(German) | V | 1 | |

| Chemical composition analysis equipment | BRAIC (China) | V | 1 | |

| Gear Checker | OSAKA(JAPAN) | ±0.001mm | 2 | |

| Hardness Tester | HRS-150(China) | V | 1 | |